| Availability: | |

|---|---|

| Quantity: | |

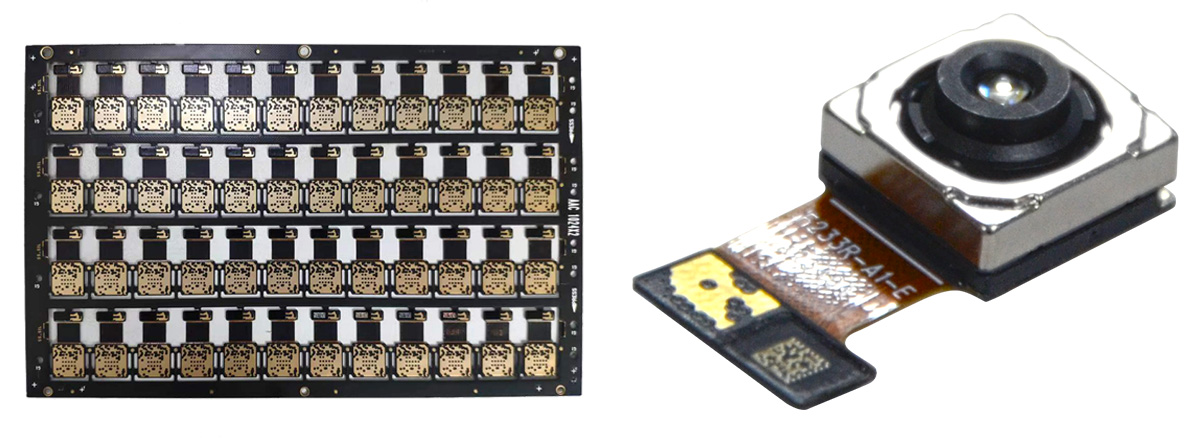

Laser Type | Picosecond |

Laser Energy | 30W |

Laser Life | ≥10000 |

Wave length | 350-355nm |

Lens | >50mmx50mm |

Product Length*Width | 350*250mm(Customized) |

Plate thickness (PI) | ≤0.3mm |

Reading requirement | Normal:Min:0.25*0.25mm |

Equipment precision | ±0.02mm |

Machine Size | Length 1-1.5m,Width 1-1.5m,Height 1-2m |

Loading and unloading mode | Carrier and guide rail automatic in and out. |

Processing method | Single platform is available |

Laser Type | Picosecond |

Laser Energy | 30W |

Laser Life | ≥10000 |

Wave length | 350-355nm |

Lens | >50mmx50mm |

Product Length*Width | 350*250mm(Customized) |

Plate thickness (PI) | ≤0.3mm |

Reading requirement | Normal:Min:0.25*0.25mm |

Equipment precision | ±0.02mm |

Machine Size | Length 1-1.5m,Width 1-1.5m,Height 1-2m |

Loading and unloading mode | Carrier and guide rail automatic in and out. |

Processing method | Single platform is available |

1. The software interface is clean and simple, with one-click import of production drawings.

2. Contactless processing with dedicated fixtures ensures no stress impact on product components.

3. Real-time smoke and dust handling during processing to ensure product cleanliness.

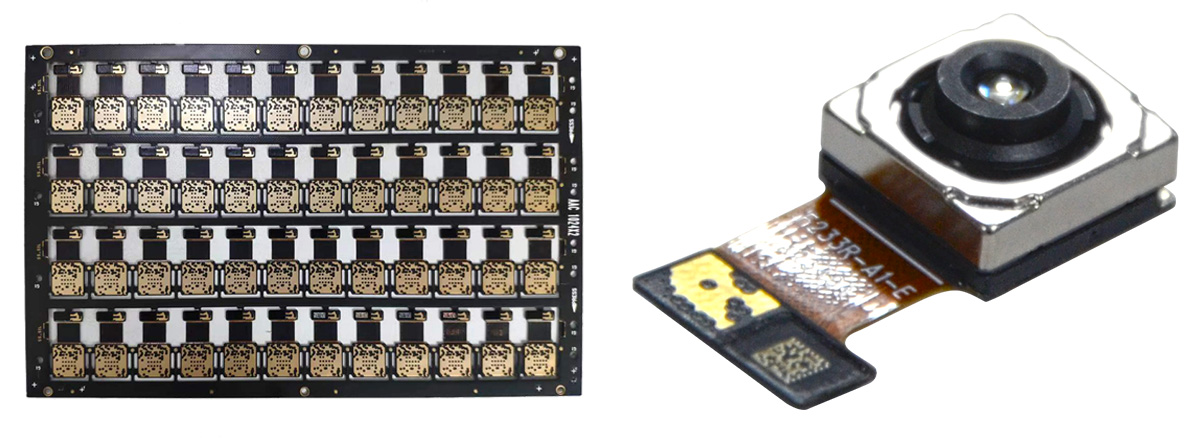

4. Suitable for precision cutting of flexible boards, rigid boards, and flexible-rigid combination boards of any shape.

5. The processing area is fully enclosed, ensuring safety protection during the processing.

6. Customized MES ports for collecting product data and tracing product information.

7. High precision, high production efficiency, UPH: 7k/h,cutting accuracy ≤ ±30um; processing thickness ≤ 3mm.

8. Achieves one-stop automated assembly line service.

1. The software interface is clean and simple, with one-click import of production drawings.

2. Contactless processing with dedicated fixtures ensures no stress impact on product components.

3. Real-time smoke and dust handling during processing to ensure product cleanliness.

4. Suitable for precision cutting of flexible boards, rigid boards, and flexible-rigid combination boards of any shape.

5. The processing area is fully enclosed, ensuring safety protection during the processing.

6. Customized MES ports for collecting product data and tracing product information.

7. High precision, high production efficiency, UPH: 7k/h,cutting accuracy ≤ ±30um; processing thickness ≤ 3mm.

8. Achieves one-stop automated assembly line service.